Inspection And Quality Control Procedures In ALT Engineering

Two independent reviews of the purchase order is where our QA begins, determining that there are no questions or conflicts regarding dimensions, material, quantities, or delivery dates.

Then all is reviewed by experienced personnel involved in the set up and production and individual inspection reports are made for each operation that is required to produce the part.

All special quality needs and instructions are documented and inspection intervals are then assigned based on tolerances, quantities or complexity of the part.

We minimize risk by tracking and analyzing every step of our manufacturing process to minimize part to part variation, and assure consistent, reliable quality for every part, every time.

Consistent quality control, from part to part, product to project, we pay attention to detail, problem-solving, researching new materials and processes, investing in technology, and building and sustaining a team of professional rapid manufacturing.

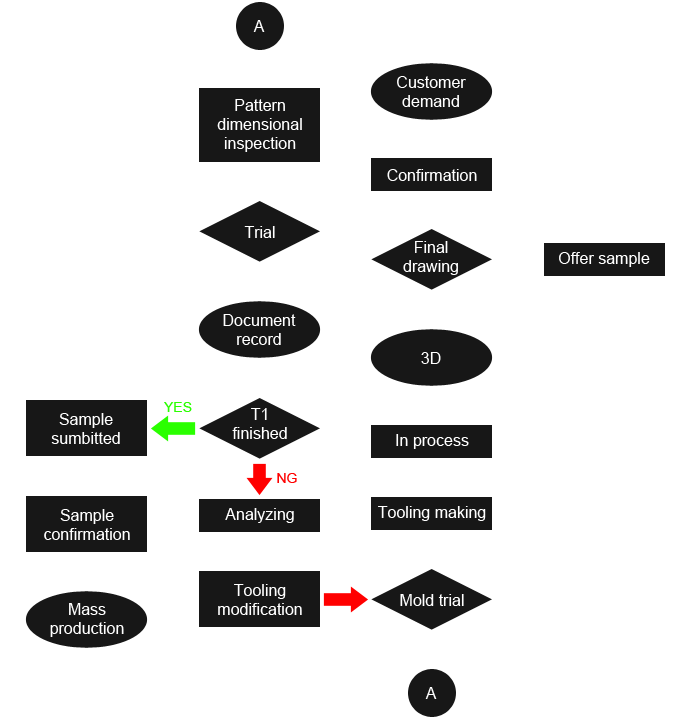

- Design for Manufacturing (DFM) review for all of your projects

- Contract and purchaser order review

- Production capacity and production plan review (PMC)

- Incoming raw materials inspection

- Samples and in-process inspection (IPQC)

- Control of nonconforming product and the implementation of corrective and preventive actions

- Final inspection and testing reports and certifications as required(OQC)

- Customer satisfaction surveys twice a year

through the whole projects from RFQs to production shipment.